Composite wrap has been known to mankind since ancient Mesopotamia (3400 BC). Back then, people glued strips of wood at different angles to create plywood.

During World War II, modern composite materials developed as glass fibers replaced heavier materials in aviation. The utilization of carbon fibers began in the second half of the 20th century. These applications span a vast area, from playing cards to the most technologically advanced vessels.

With the further development of technology, aramid fibers were introduced into composite materials. These provide even better properties.

Dynamic technological processes require fast, simple, and long-lasting solutions for repairing damaged equipment. This is especially true for pipeline systems, where downtime is undesirable and entails high costs.

What is composite wrap repair?

Composite wrap is a technology that addresses non-leaking defects like pits, dents, gouges, and external corrosion in pipelines. This method enables repairs on an operational pipeline without the need to take it out of service.

Its versatility and ability to perform repairs without interrupting pipeline operations make it a preferred choice in various industries, especially in dealing with issues related to pipeline integrity.

Industries started using composite wraps in the 1990s. They were one of the solutions for repairing damaged pipelines and other pressurized equipment.

The solution is ideal for fast and reliable repairs in the field without interrupting the flow of media through the pipeline (except in cases of leakage), which restores the initial integrity of the pipeline. ISO 24817 and ASME PCC2 standards actively standardized this rehabilitation method in 2006, establishing widely accepted guidelines for its implementation.

REINFORCEKiT 4D composite clamps

In response to market demands, 3X ENGINEERING developed composite wraps whose skeletons consist of aramid fibers (Kevlar®). These wraps provide clients with a long-lasting, reliable, easy-to-apply repair solution with as little downtime as possible and without additional maintenance.

REINFORCEKiT 4D composite clamps are designed for use on different geometries of pipelines in the temperature range from -50°C to +150°C. Apart from being used on land, they can also be used on underwater installations.

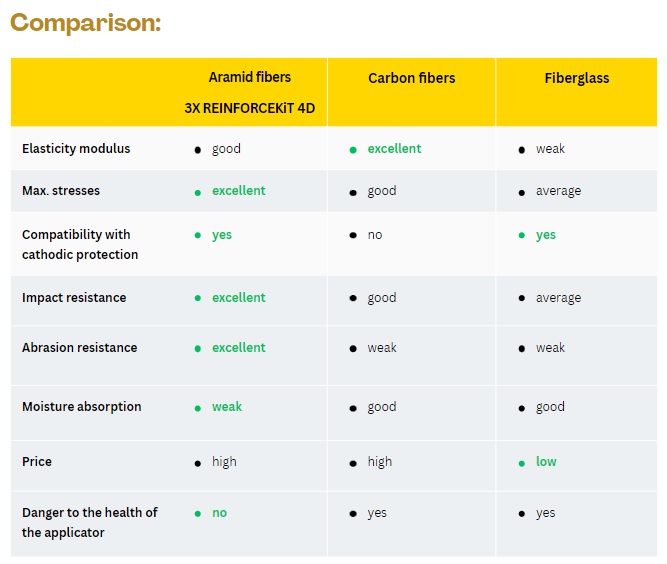

Composite clamps based on aramid fibers are an innovative solution in composite materials, and their characteristics surpass the quality of other types of composite wraps.

The following table shows the advantages of REINFORCEKiT4D composite wraps:

Constant investments in research and development have provided REINFORCEKiT 4D composite wraps by 3X ENGINEERING with superior characteristics. The quality is evident in the satisfaction of numerous clients worldwide.

Numerous independent tests actively assessed REINFORCEKiT 4D composite wrap systems. The latest achievement is type approval by LRQA.

FEROMIHIN d.o.o., as a regional representative of 3X ENGINEERING, offers its clients reliable solutions for repairing damaged pipelines with composite wraps.

Our trained and experienced employees enable us to respond to various client requests in the shortest possible time. To ensure the integrity and security of your property, contact us today.

Hrvatski

Hrvatski