The role of in-line inspection of pipeline

From an economic perspective, in transporting crude oil and natural gas, pipelines play the most important role. Pipelines are considered to be the most efficient mode of transportation. Road vehicles and tanks cannot meet the demands of the market’s supply as effectively as the pipeline structure.

Did you know detailed inspections are often quite expensive and scheduled every couple of years (ranging from 2 to 9 years)? It creates a large gap in obtaining actual data on the pipeline’s condition.

In this article, find out what an in-line inspection (ILI) is and why regular pipeline inspections are so important.

Pipeline structural integrity

The most complex task for technicians and engineers is preservation of the integrity of the pipeline structure, inside and out. The unwanted flow of substances and impurities along the pipeline can adversely affect the pipeline’s structure. Corrosion, pipeline deformation, anomalies, mechanical damage by dents, thinning of wide walls and erosion of internal and external surfaces can occur in pipelines.

The complications mentioned above can easily occur inside the pipeline. Erosion occurs due to the flow of solid grains of sand along the pipeline. Collision with the inner walls of pipeline creates the process of erosion. This results in a thinning of the wall thickness.

Over time, the problems mentioned above can become a significant obstacle to continuous gas and oil distribution through pipelines. Moreover, issues related to the weaknesses of the pipeline structure can lead to gas and liquid leaks. This can cause considerable threats to the environment and resulting in water pollution and adverse effects on marine life.

Damage to pipelines caused by corrosion and erosion can also cause the spread of toxic gases and pollute the land-based environment, resulting in a threat to human lives and the economy.

What is in-line inspection?

Pipeline problems that may occur, such as corrosion or erosion on internal and external surfaces, are detected and recorded by inspecting the condition of the pipeline walls, the process also known as the in-line inspection of pipelines (ILI tool).

In-line inspection is a technique used to assess the condition of damage within pipelines, mainly related to corrosion and erosion caused by continuous fluid flow over a long time.

This type of inspection was first applied back in 1965, when the company “Tuboscope” introduced “Linalog”, a device for determining the place of metal loss on the walls of the pipeline.

The in-line inspection technique is a form of non-destructive preventive inspection for pipeline maintenance to determine the possibility of corrosion, erosion, cracks in metal walls inside the pipeline, and other types of damage that can potentially lead to catastrophic damage to pipeline structures.

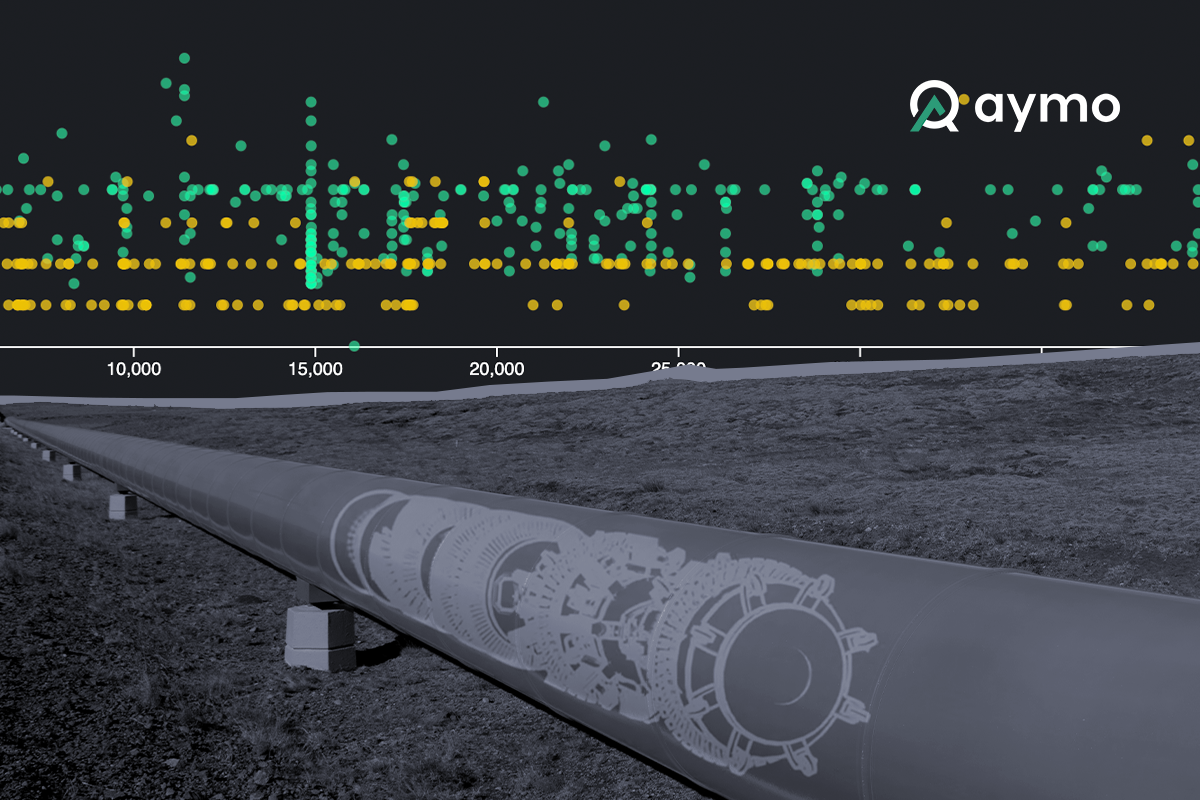

Data can also be recorded and interpreted through AYMO software, independent of the vendor who will perform the review. AYMO is a software platform for pipeline integrity management that focuses on the end user’s needs and simple workflows. The system enables pipeline monitoring, corrosion growth prediction, anomaly detection, pipeline repair, maintenance planning, and documentation management.

How is the pipeline inspection process carried out?

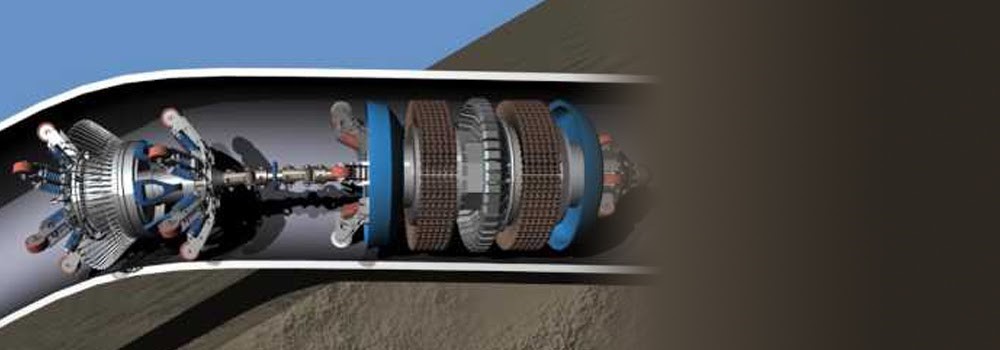

Different kinds of equipment are used to inspect the pipeline. The in-line inspection involves the use of technologically advanced tools. One of the tools used during the in-line inspection is “smart cleaners” (Intelligent pigs) that provide information about the general condition of the pipeline and its parts. Most devices collect samples and determine the damage’s type, position, and size.

The “intelligent pig” for pipeline inspection is a measuring device with different dimensions. The device passes through the pipeline, collecting data and using the latest technologies (GPS systems and software), representing the basis for control and maintenance of the pipeline. For these devices to be used, the pipelines must have appropriate infrastructure that accepts the installation of the ‘pig’.

Before checking the inside condition of the pipeline, the pipeline should be cleaned and inspected using a smart cleaner. This tool records data such as wall thickness and recesses in pipelines. Furthermore, the in-line inspections with devices such as ‘smart pigs’ are crucial because they allow continuous pipeline operation during inspections without stopping or interrupting production.

There are several construction versions of the device for recording the pipeline’s wall. Still, they are most commonly used to determine the geometry of the pipeline and to detect metal loss caused by corrosion. Some of the other purposes include the detection of leaks and ruptures of the pipeline, the collection of samples of transported fluid and the recording of the interior of the pipeline with a camera.

Pipeline corrosion

Pipeline corrosion is the leading cause of pipeline failure due to its inherent measurement and detection difficulties. Nowadays, various tools help us assess and measure corrosion growth rates. Nonetheless, the most important thing in the whole process is prediction and prevention of pipes rupture based on given data. With the help of AYMO software, it is possible to anticipate the occurrence of corrosion and act preventively. AYMO is an innovative solution that provides analytical capabilities for data analysis, maintenance, and pipeline integrity monitoring.

Our in-line inspection (ILI) technologies provide comprehensive hazard assessment and the ability to detect cracks and various anomalies, corrosion and metal loss, dents, and the like.

There are several ways in which pipeline integrity management software can help you:

- Data management and integrity processes: The goal is to get accurate information on time and make effective decisions.

- Providing visualization tools: Efficient software systems present information in an intuitive way that helps you rationalize the complex relationships between anomalies and the pipeline environment.

- Effective reporting: It involves delivering complex results that decision-makers must clearly understand and, as a result, take the necessary effective actions.

- Maintenance planning and cost forecasting: The system enables the creation of work orders and maintenance plans in addition to budgeting, to find optimal activities and the most efficient ways of repairing pipelines.

Why is a pipeline inspection necessary?

Factors that most often affect the shortening of the service life of pipelines are corrosion and external influences (mechanical damage), design errors, and errors in repairs. That is why it is important to regularly inspect and maintain pipelines and record the condition and data, to make them available to those in charge of pipeline management.

Whereas the pipeline structures can stretch for hundreds of kilometers, oil and gas industry projects reach multimillion-dollar amounts. Regardless of the size of the pipeline, sudden damage can cause massive damage in a short period. That is why prevention is important. Even if the pipeline shows no signs of damage or indications of leakage, routine inspection is the first line of defense against failures and should be part of your asset management plan.

Investing additional resources to protect the pipeline to ensure its integrity and prevent corrosion is critical for the industry. In addition, it is highly important to clean the inside of the pipelines regularly and carry out security checks to meet technical requirements, thus ensuring their integrity for a longer period.

Without proper access to the vast amounts of data available, you could miss significant security and performance improvements. For quality and proper system management, it is necessary to collect enough data. Such an analysis can be carried out with the help of inspection methods and system monitoring. All this leads to the digitalization, which presents simple and organized approach to managing the pipeline network.

The right tools and pipeline management softwares

With the development of technology, pipeline management is greatly facilitated, and the use of management tools and software becomes inevitable. The tools used today provide a wide range of options, from reviewing system components, planning alternatives, to mapping and digitizing systems.

Experience is crucial when it comes to any type of pipeline inspection. Our professional services include consulting, procuring, installing, and maintaining oil and gas pipelines.

If you want to maximize your revenue, remember that pipeline supervision, control and maintenance are the foundations of a successful business. For any further questions, please contact us and extend the life of your pipelines. Our expert team will ensure the level of service your pipelines deserve.

Hrvatski

Hrvatski Русский

Русский العربية

العربية