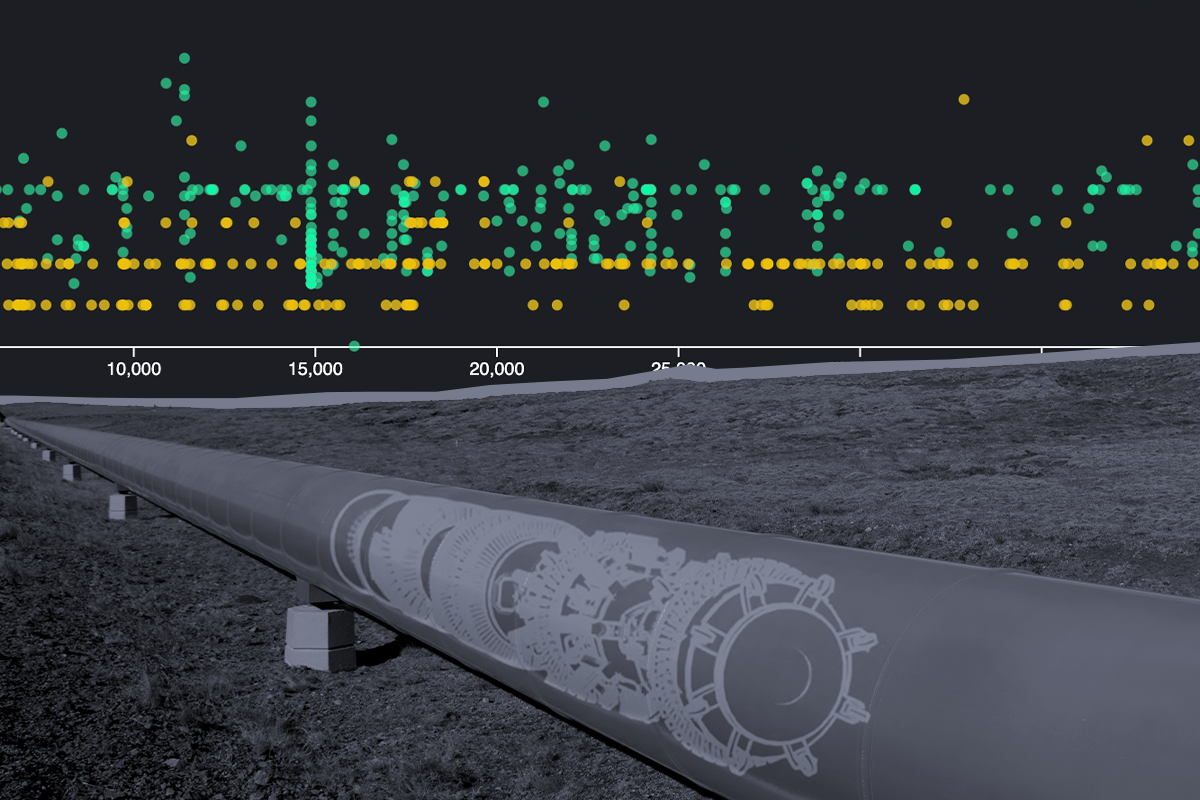

Where data meets intelligence

Taking care of your pipelines

Vendor-neutral

AYMO supports all in-line and other data providers/suppliers on all inspections. In addition, it allows input from any third party performing inspection, cleaning or any other activity related to the pipeline. The system interprets the obtained data, analyzes it and helps in decision-making. Vendor neutrality affects the reduction of costs when choosing the most favorable supplier.

Planned maintenance

The system enables the creation of customized work orders (dig sheet) and the planning of optimal repair costs, suggesting the highest quality materials and the best methods. Our comprehensive Activity & Repair module offers a wide range of functionality to help operators plan and monitor maintenance processes. In addition to bringing savings, the system enables monitoring of progress while simultaneously improving all activities performed on the pipeline.

Corrosion control

AYMO uses advanced algorithms that allow users to simulate the growth of corrosion on pipelines, facilitating the process of making timely decisions.

Pipeline builder

The system provides operators with the possibility of creating a virtual pipeline (using basic elements) that will best suit their needs and requirements, which will enable better visibility and determination of the actual situation in the AYMO system.

Global availability

Cloud & Web based

PROCESS BASED

A structured approach to integrity

In addition to supporting pipeline integrity, the AYMO system helps manage risks at all stages of the pipeline’s life cycle – from inspection data analysis to management risk assessment and risk mitigation planning.

Hrvatski

Hrvatski Русский

Русский العربية

العربية