Quality defines our work vision

3x Engineering

Feromihin has exclusive right to distribute 3x Engineering products in Croatia, Bosnia and Herzegovina, Slovenia, Serbia, Montenegro and Kosovo.

REINFORCEKiT®

REINFORCEKiT® 4D (R4D) works according to the principle of the so-called “wet” application. It is wrapped helically around the pipe, mechanically strengthening the damaged part of the pipe. The amount of layers is determined depending on the pressure in the pipe, temperature, diameter and thickness, as well as the depth and length of the pit, the type of steel and the location of the pipe. The details of the repair procedure, as well as the type of material, are determined with the help of 3X REA software after entering all the necessary information (in accordance with ASME B31G, ISO 24817 and ASME PCC-2 codes and standards.

REINFORCEKiT® 4D is recommended for the repair and reinforcement of pipelines operating at temperatures between -50°C (-58°F) to +150°C (+302°F) and subject to external/internal corrosion, leakage (dedicated procedure for repairs under voltage), dents and mechanical damage. The system restores pipe integrity and prevents further deterioration. This composite wrapping is made of 400 g/m² Kevlar® tape and strongly reinforced ceramic epoxy resin.

innovative solution for repair process

Product range

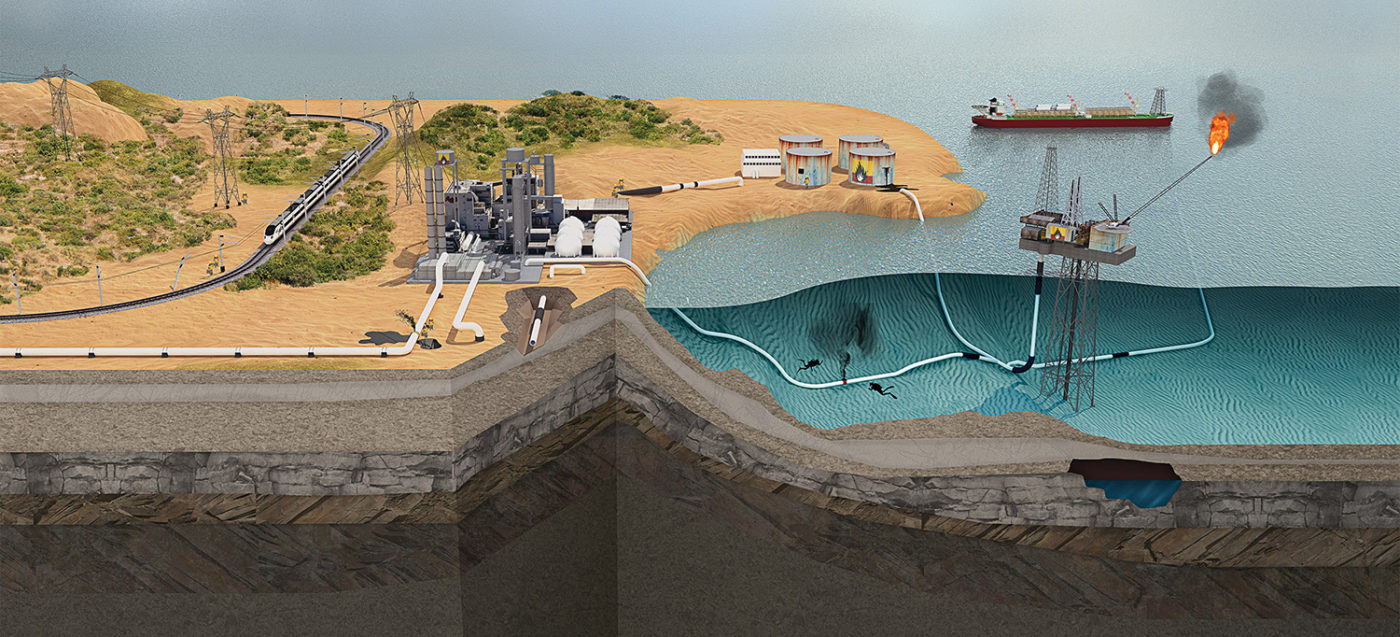

PROCESS BASED

STOPKiT®

STOPKiT® uses currently the most effective repair procedures. By using it, leaks in pipelines can be stopped remotely in just a few minutes.

It stops various types of leaks (oil, gas, water…) on pipes with diameters from 2″ to 56″, and is also successfully applied on parts of specific shapes (oval pipe, elbow) and on welds.

This patented product is used in situations of high urgency. It is available in several models (depending on the diameter of the pipe and opening), as well as for different environments (onshore, offshore and underwater).

When the diameter of the hole is less than 25 mm mm (patch size 50×100 mm), the leak can be stopped with a maximum pressure of up to 120 bar. If the diameter of the hole is up to 50 mm (patch size 100×100 mm), the leak can be stopped with a maximum pressure of up to 50 bar), depending on the pipe diameter and temperature. A special patch (size 50×50 mm) is designed for STOPKiT® of small diameters (2″ and 3″) to stop (sealing) leaks at openings up to 20 mm with a maximum pressure of 150 bar.

The installation can be carried out without interrupting the pressure in the pipeline.

Hrvatski

Hrvatski Русский

Русский