For years, pipeline corrosion protection has been one of the most important factors when designing and maintaining new pipelines.

Although the existing pipeline protection methods protect thousands of kilometers of pipelines, they show certain shortcomings. This opens up space for new innovative solutions in corrosion protection.

Conventional pipeline corrosion protection systems

Conventional systems for corrosion protection rely on materials with chemically cross-linked structures. During application, specific mechanical properties are added to ensure the system’s stability for a particular period.

The leading causes of the failure of conventional corrosion protection systems are:

1) Inadequately designed corrosion protection system;

2) Poor surface preparation/poor application;

3) Influence of external factors from the working environment (humidity, salinity, wind, temperature). Engineers are constantly trying to devise solutions that would reduce the mentioned causes to a minimum and ultimately eliminate them.

Innovative systems are created with the exact opposite: a non-crosslinked amorphous visco-elastic structure. Polyisobutene proved to be the most adequate polymer that meets the set requirements.

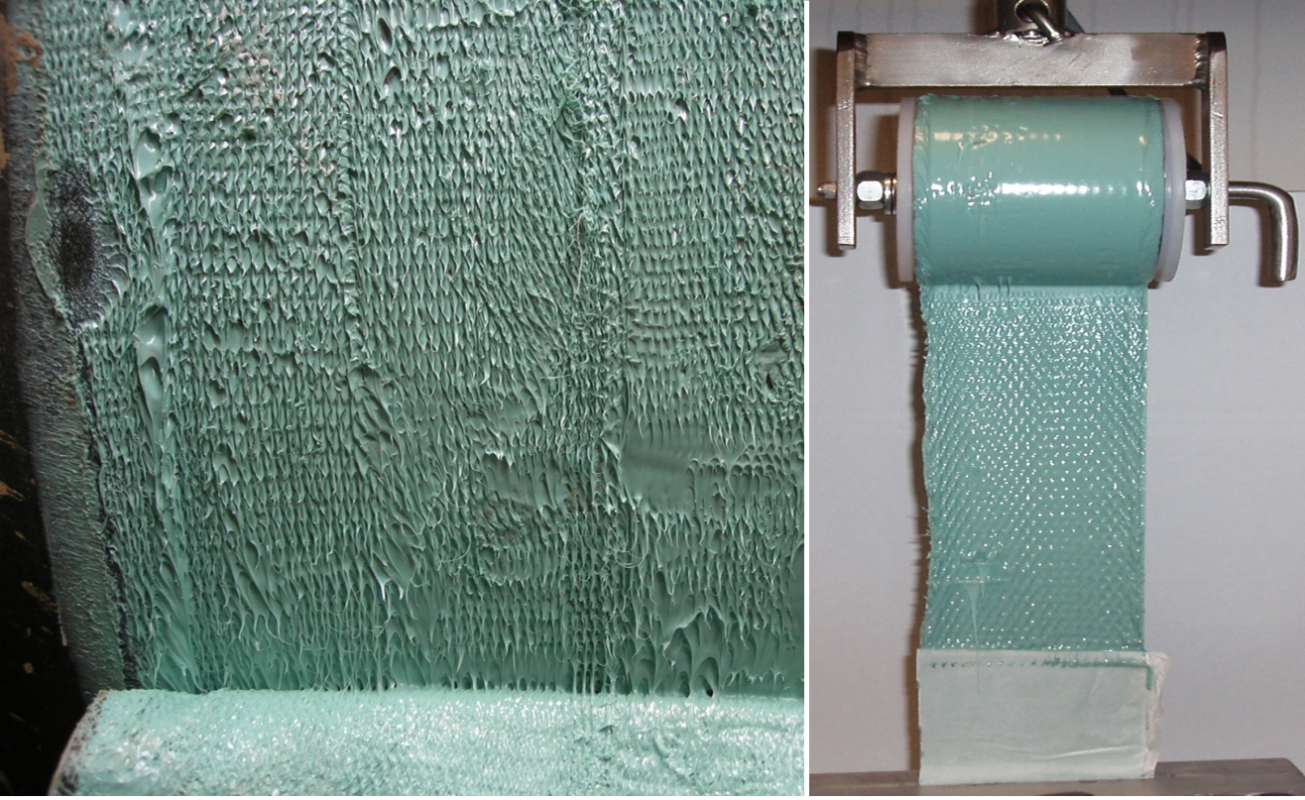

Covalent bonds connect the structural units of polyisobutene, and the polymer chain does not cross-link, which leads to the so-called “cold flow”. This means that even at low temperatures, polyisobutene will eventually fill the smallest pores on the material’s surface, eliminating the possibility of osmosis and moisture migration between the surface and the protective layer.

Innovative STOPAQ material

STOPAQ material based on polyisobutene will remain semi-liquid throughout its working life with strong adhesion forces to the surface, thanks to which the material has self-healing properties. At the same time, it remains resistant to aging and the influence of chemicals and is impervious to moisture, oxygen, and bacteria.

Innovative visco-elastic STOPAQ® materials based on polyisobutene. These materials provide end users with a longer service life, reduced maintenance costs, the highest level of corrosion protection, and faster, simpler, and cheaper surface preparation and system application that does not require special equipment or special applicator skills.

Application of the STOPAQ® system in practice is relatively simple. It is sufficient to prepare the surface with manual or electric tools up to the St2/St3 level, and it is necessary to ensure that the surface is clean and dry.

Preparation of the surface by abrasive cleaning (“sandblasting”) is not necessary because STOPAQ® materials do not require a certain level of surface roughness (profile).

Also, the application does not require a primer, which is possible in the temperature range from -45°C to +120°C. The application is mostly done manually, and minimal employee training is required due to its simplicity.

Backfilling of underground pipelines is possible immediately after the completion of the system application. It is not necessary to wait for the system to harden as in the case of conventional systems, thus reducing the time required to execute work and, thus, the total costs.

STOPAQ® corrosion protection system

The STOPAQ® corrosion protection system is compatible with the cathodic protection system, and due to strong adhesion forces, it prevents cathodic disbondment and creep.

Regarding safety and environmental protection, STOPAQ® systems meet the highest standards because the materials are non-toxic and safe for employees and the environment, and the only waste generated during application is cardboard packaging and plastic film.

The rich experience that we at FEROMIHIN, the regional distributor for STOPAQ®, have gained through numerous completed projects allows us to offer our clients innovative and long-lasting solutions for corrosion protection.

Prevent pipeline corrosion before it becomes a problem. To ensure the integrity and safety of your property from corrosion, contact us today.

Hrvatski

Hrvatski