Pipe protection is imperative to ensure uninterrupted supply and safety when transporting oil, gas, and other crucial substances.

The piping system is one of the most crucial components of the oil and gas industry because it transports these media from one place to another.

Their seamless operation is important to the functioning of industries and communities. However, the harsh realities of corrosion, external forces, and environmental challenges constantly threaten their well-being.

Understanding the operational system and the oilfield environment is essential to effectively eliminating corrosion in the system. Identifying the key factors contributing to the corrosion issue is the first step in addressing and mitigating the problem.

In this blog post, we will explore the importance of pipe protection in the oil and gas industry and the various methods for protecting pipes.

Why is pipe protection important?

Pipes are exposed to environmental factors, such as harsh weather conditions. Other factors negatively impacting pipes are high pressure, corrosive chemicals, and abrasive materials. These can cause damage to the pipes, resulting in leaks, ruptures, or potential disasters.

Pipe protection increases the pipes’ lifespan, prevents production downtime, ensures safety, avoids environmental catastrophes, and reduces maintenance costs.

What is a pipe protection mesh?

A pipe protection mesh, or a rock guard, shields pipelines from potential damage, especially in rocky backfill.

The primary purpose of a rock mesh is to act as a barrier between the pipeline and abrasive materials, such as rocks or sharp objects, that may be present in the surrounding soil or backfill during construction.

Key features and characteristics of rock protection

- Material composition: Pipeline protection mesh is typically made from durable materials such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE). Material selection is crucial to ensuring the mesh’s ability to withstand mechanical stresses and environmental conditions it may be exposed to.

- Mesh structure: The material has a flexible, mesh-like structure and design that allows it to conform to the shape of the pipe and provides coverage along its entire length.

- Installation: Mesh is placed around the exterior of the pipeline to act as a protective barrier. Installation involves wrapping and securing the protective mesh around the pipeline.

- Protection against abrasion: The primary purpose of protective mesh is to shield the pipeline from abrasion, rocks, stones, or sharp objects. This is particularly important in rocky environments where the risk of mechanical damage to the pipeline is higher.

- Preservation of coating: Protective mesh preserves anti-corrosion coatings on pipelines. By preventing direct contact between the pipe surface and abrasive materials, the mesh helps maintain the effectiveness of corrosion-resistant coatings, ensuring the pipeline’s longevity.

- Versatility: These meshes have various applications and are used for protecting oil pipelines, gas pipelines, water and sewage pipes, and other critical infrastructure installations where protection against external abrasion is crucial.

What is used to protect pipes from damage caused by rocky backfill?

Protecting pipes from damage caused by rocky backfill is crucial to ensuring the integrity and longevity of the pipeline. There are various methods of pipe protection, ranging from basic to advanced:

Padding material

Placing a layer of softer material, such as sand or pea gravel, between the pipe and the rocky backfill can help cushion the pipe and reduce the direct impact of rocks.

Geotextile fabric

Wrapping the pipe with geotextile fabric can provide additional protection. This fabric is a barrier, preventing direct contact between the pipe and the rocky backfill.

Cushion boxes

Cushion boxes, or pipe support blocks, are pre-formed concrete or plastic blocks designed to cradle and support the pipe. These boxes create a protective barrier around the pipe, helping to distribute the load and reduce the risk of damage from rocky backfill.

The choice of method depends on factors such as the type of pipe, the characteristics of the rocky backfill, and the project’s specific requirements. It is essential to consider the potential for movement and settlement of the backfill over time and choose protective measures suitable for the conditions in which the pipeline is installed.

How do you protect pipes from corrosion?

Protecting pipes from corrosion is crucial to ensuring their longevity and maintaining the infrastructure’s integrity. Here are several methods commonly used to protect pipes from corrosion:

Coatings

1. Factory-applied coatings (PE, PP, FBE)

The abbreviations PE, PP, and FBE refer to specific types of coatings commonly used in industrial applications. They play crucial roles in enhancing the durability and performance of various industrial products.

These coatings are applied to various factory materials and products for protection, corrosion resistance, and other functional properties.

Polyethylene (PE):

Polyethylene is a widely used thermoplastic polymer for coating steel pipes and structures. Primarily applied in the oil and gas industry, PE coatings provide corrosion protection for pipelines and are also utilized in water pipelines and similar settings requiring robust corrosion resistance.

Polypropylene (PP):

Polypropylene (PP), a thermoplastic polymer, is commonly used to coat steel pipes and for various industrial applications, particularly in the oil and gas industry. PP coatings improve corrosion protection, especially in environments that resist aggressive chemicals, such as those in chemical processing applications.

Fusion-Bonded Epoxy (FBE):

FBE, a thermosetting epoxy powder coating applied through fusion bonding, is extensively used in the oil and gas industry to protect pipelines from corrosion. Its applications extend to various sectors requiring durable and corrosion-resistant coatings.

The choice of coating depends on the application’s specific requirements, including the type of material, environmental conditions, and desired performance characteristics.

2. Corrosion protection tapes

Tapes for protection against corrosion are essential in various industries, particularly in the oil and gas sector and pipeline infrastructure. These tapes are designed to provide a barrier against corrosive elements, moisture, and environmental factors that can degrade the integrity of metal surfaces. Polyisobutene (PIB), Butyl, and Petrolatum are three common corrosion protection tapes.

Polyisobutene (PIB) tape:

PIB tape consists of polyisobutene, a synthetic rubber known for its excellent impermeability to water and gases. It is widely used for corrosion protection in pipeline joints, flanges, and other irregular shapes. It provides an effective barrier against moisture and prevents the intrusion of corrosive elements.

Butyl tape:

Butyl tape is made from a synthetic rubber known as butyl rubber. It is a common choice for corrosion protection due to its excellent sealing properties and resistance to water and chemicals.

Petrolatum tape:

Petrolatum, or wax tape, is made from a synthetic fabric infused with a petrolatum compound, fillers, and anti-corrosion agents. It is commonly used for below-ground and underwater applications and protects pipes, valves, bends, flanges, and other metal structures from corrosion caused by soil, water, and other corrosive substances.

3. Conventional coatings

Conventional coatings, such as epoxy and polyurethane, protect pipelines from corrosion, abrasion, and other environmental factors. Due to its excellent protective properties, these coatings are widely used in the oil and gas industry, water treatment facilities, and various industrial applications.

Epoxy coatings:

Epoxy coatings are typically composed of epoxy resins and a curing agent. The curing process involves a chemical reaction that forms a hard, durable, and chemically resistant surface.

Epoxy coatings have exceptional corrosion resistance. They create a barrier that shields the pipeline from corrosive substances in the surrounding atmosphere or transported fluids. They also resist various chemicals, making them suitable for pipelines transporting corrosive substances.

Polyurethane coatings:

Polyurethane coatings are formulated using polyisocyanates and polyols. Combining these components results in a coating with excellent flexibility and durability. One of the key advantages of polyurethane coatings is their flexibility. This property allows the coating to withstand substrate movements and expansions without cracking, making it suitable for pipelines exposed to temperature variations.

Polyurethane coatings offer high abrasion resistance and good resistance to ultraviolet (UV) radiation, protecting the pipeline from the degrading effects of sunlight in outdoor applications.

Cathodic protection

Cathodic protection involves applying an electric current to the metal structure, which counteracts the electrochemical reactions that lead to corrosion. This method inhibits the oxidation process and prevents corrosion damage by designating the protected metal surface as a cathode in a corrosion cell, extending the pipeline’s lifespan.

Corrosion inhibitors

Corrosion inhibitors can be added to the fluid within the pipe to reduce or prevent corrosion. These chemicals work by forming a protective layer on the metal surface.

Insulation

Applying insulation to pipes can protect them from external and internal corrosion. Insulation helps to maintain stable temperatures, reducing the likelihood of condensation and corrosion.

Proper design and installation

Proper design and installation practices can prevent corrosion by avoiding conditions that promote it, such as water accumulation, uneven coatings, or inadequate protection measures.

Monitoring and maintenance

Properly inspecting and maintaining pipes is essential to identifying and addressing corrosion issues. You can use monitoring systems, like corrosion coupons or electronic sensors, to track corrosion rates.

Proper grounding

Good grounding and bonding stop corrosion from stray electrical currents in the soil.

The importance of maintenance and inspection

Corrosion monitoring and prevention have been subject to engineering concerns and investigation for decades. It was causing an annual loss estimated at 10% of global materials, consuming over 42 billion dollars within the developed nations and depleting the economies of developing countries. This has made corrosion management and prevention a significant concern within the oil and gas industry, pipeline management, and operational settings.

Regular inspection and maintenance of pipes can help identify potential issues before they escalate into critical problems. Pipe cleaning is essential to eliminate debris that may cause damage and disrupt the pipes’ proper functioning.

Solution: Advanced pipeline protection with structured plastic mesh

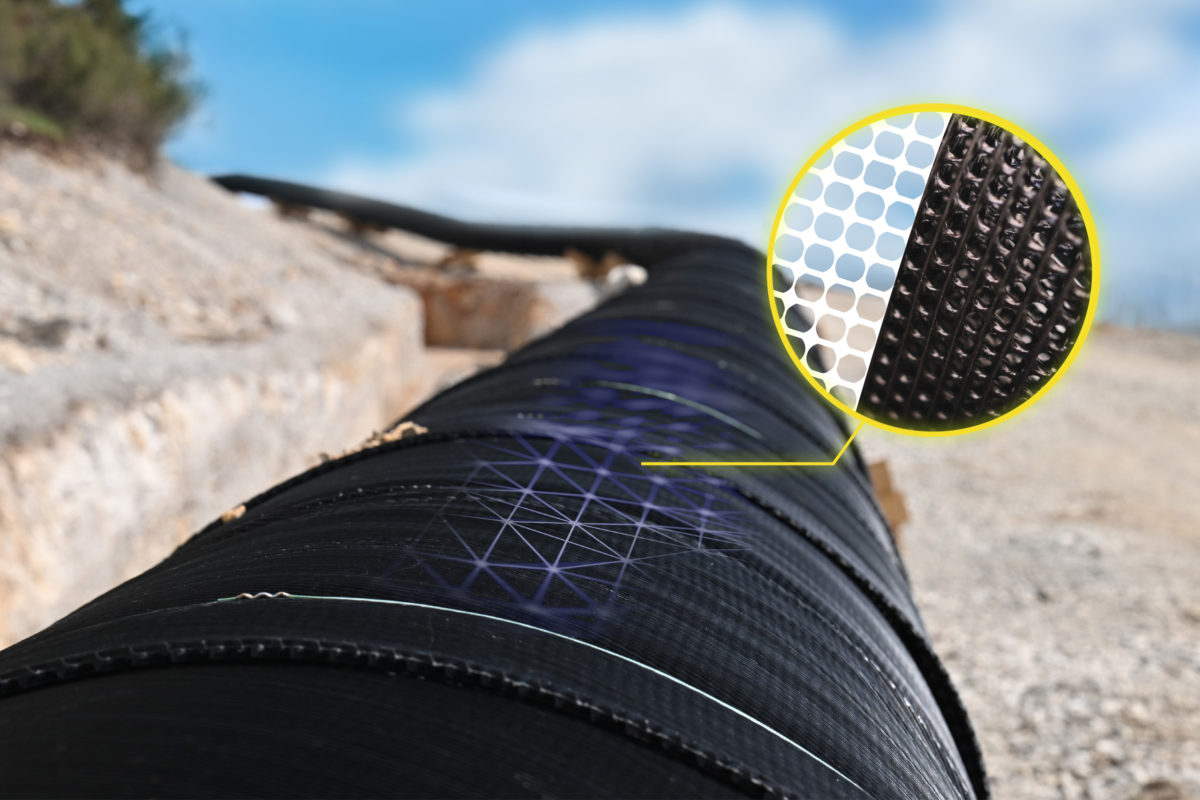

AEGIS Rockshield, a new product by Feromihin for pipeline protection and support, was created to negate all the risks associated with challenging environments, particularly rocky backfill scenarios.

This three-dimensional, diamond-structured plastic mesh is engineered from polyethylene.

The resulting diamond-shaped mesh pattern provides a robust shield for pipeline corrosion coatings, ensuring the integrity and longevity of the infrastructure.

Its application extends to offshore pipes, safeguarding coating materials during pipe lay, rock placement, and infill operations.

Key features:

- AEGIS Rockshield provides a robust cushioning structure that absorbs impact and protects pipelines from uneven backfill.

- The material is chemically inert, ensuring compatibility with various pipeline coatings and resistance to corrosive elements.

- It is impervious to rot, ensuring long-lasting protection in diverse environmental conditions.

- Available in rolls or pads with high impact and tensile strength, ensuring durability and reliability.

- The open mesh structure facilitates water flow, preventing water accumulation and potential corrosion issues.

- It remains effective in all climates, unaffected by temperature extremes and wet weather.

- AEGIS Rockshield is easy to install, offering a practical solution for pipeline protection in challenging terrain.

Safeguarding the lifelines of industry

Implementing advanced pipe protection solutions is a primary strategy for safeguarding pipelines and ensuring long-term reliability.

By employing cutting-edge technologies, corrosion-resistant coatings, and innovative methods, the industry can fortify pipelines against the detrimental effects of environmental factors and enhance their durability.

Investing in pipe protection prevents unwanted disasters and offers long-term benefits. It lowers maintenance costs, improves production efficiency, increases the lifespan of the piping system, and reduces the risk of costly shutdowns due to pipe damage.

As we prioritize the integrity of our pipeline infrastructure, these advanced solutions emerge as crucial components in maintaining a resilient and reliable network for the future.

Interested in our product? Send an inquiry. Our committed team is ready to help you discover the perfect solution for your operation.

Hrvatski

Hrvatski